The higher the LED light efficiency, the lower the CRI?

The higher the LED light efficiency, the lower the Color Rendering Index? It is obvious that this view is not right. Firstly, this causal relationship of this logic is somewhat reversed, it is not because light efficiency is low and therefore CRI is high, but in order to improve CRI it sacrifices some light efficiency.

Factors affecting the CRI

Nowadays, commercial LED is mostly coating (YAG) yellow phosphor can be excited by the blue light on the blue LED chip, we usually call it yellow powder. The blue light from the chip and the yellow light from the fluorescent powder complement each other to form white light.

Shuji Nakamura, the inventor of the blue light LED

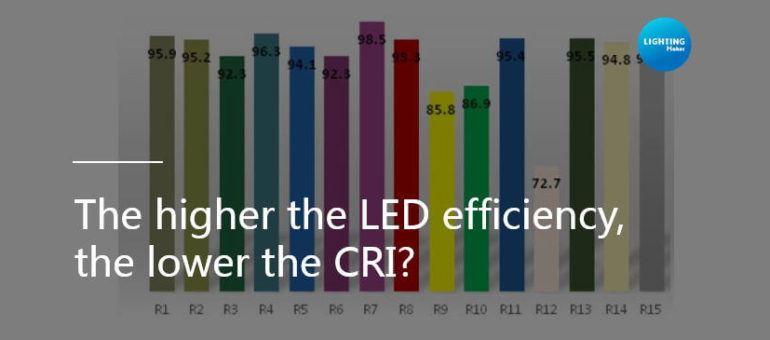

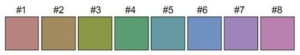

If you want to improve the color rendering of LED, It involves the calculation of the CRI. Generally, the calculation of color rendering index is R1-R8, and the chromatography is relatively narrow.

Eight color plates for Ra

However, it’s also missing a very important spectrum-the special explicit reference R9, red R9 (saturated red) is an indicator that evaluates the quality of red display. They play an irreplaceable role in the studio, studio and other occasions that require the real reproduction of skin color, as well as the color restoration of fruits and vegetables fresh meat.

R9 is also an important indicator to measure LED color rendering.

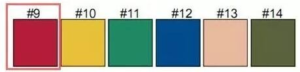

The difference between the low R9 and high R9

Therefore, it is far from convincing to use R1-R8 as the standard in Ra evaluation of CRI. In real life, you can often hear many manufacturers declare:

CRI>90,R9>50

So how do they do that?

How does the manufacturer improve the LED CRI?

There’s a saying that goes, “Lack what fill what”. It can’t be more accurate to use it here. Since it lacks R9, so we add R9. How do you make it up?

Add red phosphor to make up the deficiency of LED red spectrum and adjust the CRI of white light LED.

It involves addition concentration, for example, if a LED color rendering index is 70, you want to increase to 80 color rendering index, you may just need to mix a little bit of red phosphors, but if you want to reach 90 color rendering index, it requires exponentially increase the concentration of the mixed with pretty.

This is not without cost. The too high concentration of red fluorescent powder will cause the color point of LED to deviate from the Planck curve, causing serious color deviation.

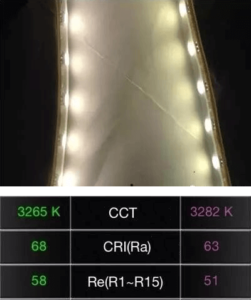

The color temperature of the two led strip is almost the same,but we can see it’s obvious different

The color temperature is same -around 3,200k, but we can see a significant difference by our naked eye.

Therefore, the proportion of red phosphor in the formula is different, and the effect on the CRI and color temperature is different.

In addition, red phosphors have a feature: The optical conversion efficiency is low when excited, Therefore, the LED’s overall optical performance will be pulled down virtually.

So, the impact of red phosphors on the color rendering index and photosynthetic efficiency is obvious:

1, The Excessive concentration of red powder will lead to serious LED color deviation.

2, The optical conversion efficiency is low when the red powder is excited, it will pull down the overall LED light performance.

How to improve the color index of LED while ensuring the light efficiency, and to ensure that the color deviation is not serious, every LED chip factory has its own “fluorescent powder formula”, which is also their core secret.