Soft light strips, hard light strips, wall washers, brackets, how should they be distinguished?

Frequently, foreign customers are asking:” soft light strips, hard light strips, wall washers, brackets, these common long strips, how is it distinguished? Where is it generally used?”

работни обувки fw34 steelite lusum s1p 38

normamascellani.it

covorase man

bayern münchen spieler

karl sneakers

addobbi fai da te matrimonio

prestonstadler.com

spoločenské šaty pre moletky

fingateau.com

lifeonthevineministries.com

Below, we summarize their differences and usage suggestions for these types of products.

Low voltage soft light strip

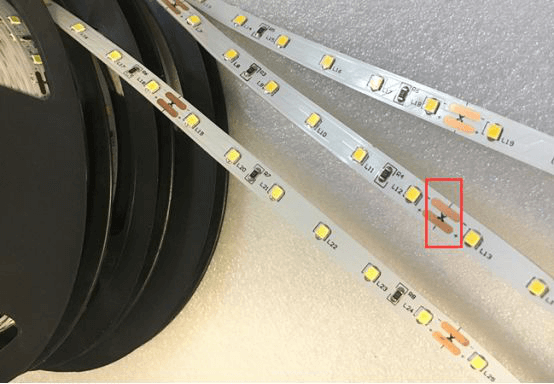

The following figure is one of our most common low-voltage light strips, with 12V and 24V.

The low-voltage soft lamp is very convenient to use: after tearing off the protective paper of the adhesive, it can be placed on a narrower place where the hope is full, such as bookcases, showcases, kitchens, etc. the advantage is that the shape can be changed, and there is no problem in turning and arcing.

There is a scissors mark on every small section of the lamp strip, which means that this place can be cut. How long is it usually cut once? Depends on the operating voltage of the lamp strip. For example, this Oup 24V lamp strip is a six-bead and a scissor mouth, generally, each length is 10cm. Like some 12V, it is a cut of 3 beads, about 5cm.

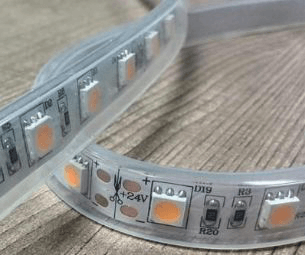

▲Light strip with protective cover.

Otherwise, we can see that some light strips have a plastic protective cover, and some do not, but it is obvious that the protective cover is not to prevent electric shock(low pressure is relatively safe), but the user requirements are slightly different, such as the upper cloth the lamp is easy to dust and dust, and it is recommended to use a protective cover for easy cleaning.

Since the low-voltage lamp strip is relatively thin and the ability to over-current is relatively weak, it is mostly 5m. if the light strip required for the use of the scene is very long, then multiple wiring stations are required, and many transformers are used. In addition, there is also a 20m one, and the substrate of the lamp strip is made thicker to increase the current carrying capacity.

2 High pressure light strip

High-pressure lamp strips are generally 1m sheared or even 2m sheared. Remember not to cut from the middle, otherwise, the whole set of lights will not light. Suppose we only need a 2.5m strip, what should we do? Cut 3m out, then fold the excess half a meter back, or wrap it with black tape to prevent light leakage and avoid partial over-brightness.

Where is the high pressure lamp strip generally used?

First of all, because the whole lamp is 220V high pressure, it is dangerous if it is used in places such as steps and guardrails that can be easily touched. Therefore, it is recommended to use a place where the position is relatively high and people can’t touch it, such as the ceiling light trough. Be sure to use a high-pressure lamp strip to have a protective cover.

The application distance is also long, the high-voltage lamp strip can be continuous for 100m, and it can be cut every 1m, and a driver with 100m is no problem.

Relatively speaking, the high-voltage lamp belt power will be relatively high, and some 1m can achieve 1000 lm, or even 1500 lm. However, it should be noted that the general high-voltage lamp strips are strobed, so choose the appropriate driver.

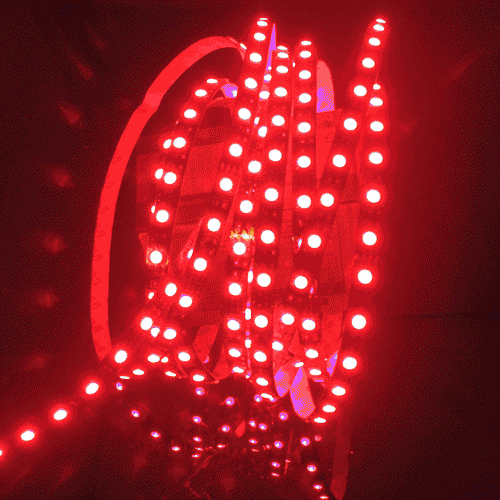

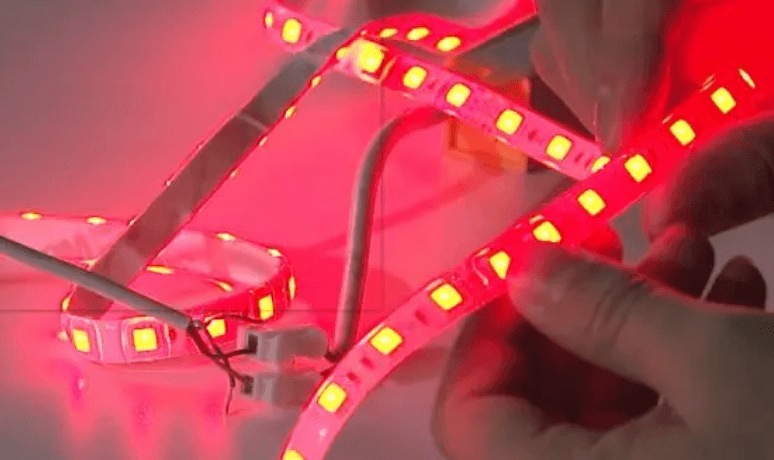

3 RGB color light strip

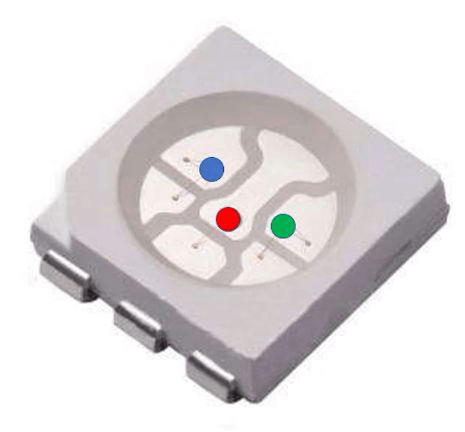

There are three cores in each bead, so each bead can emit three colors. When three beads are energized, they can mix different colors of light.

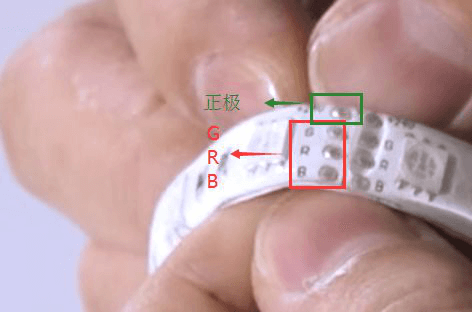

▲The four solder joints are RGB and positive.

Only connect positive and red, the light emitted is red

Connect the positive electrode to red and blue, and the light that is mixed is purple.

In addition, you can adjust the current and input control to mix richer colors.

Taken together, the benefits of the flexible strip are that the length can be flexibly cut and bent at will, making it easy to outline the shape of the curve.

4 Light Bar

The hard light bar is essentially the same as the soft light strip.

In appearance, the soft light strip is turned into a hard light strip after it is put on a hard aluminum plate. This makes its shape more regular, and there is no such thing as bending and bending of the soft light belt.

After the milky white acrylic is applied, the light of the light bar becomes uniform, and unlike the soft light strip, the light bulbs are often seen, so the hard light strips are often used for linear decorative lighting

5 Wall washer

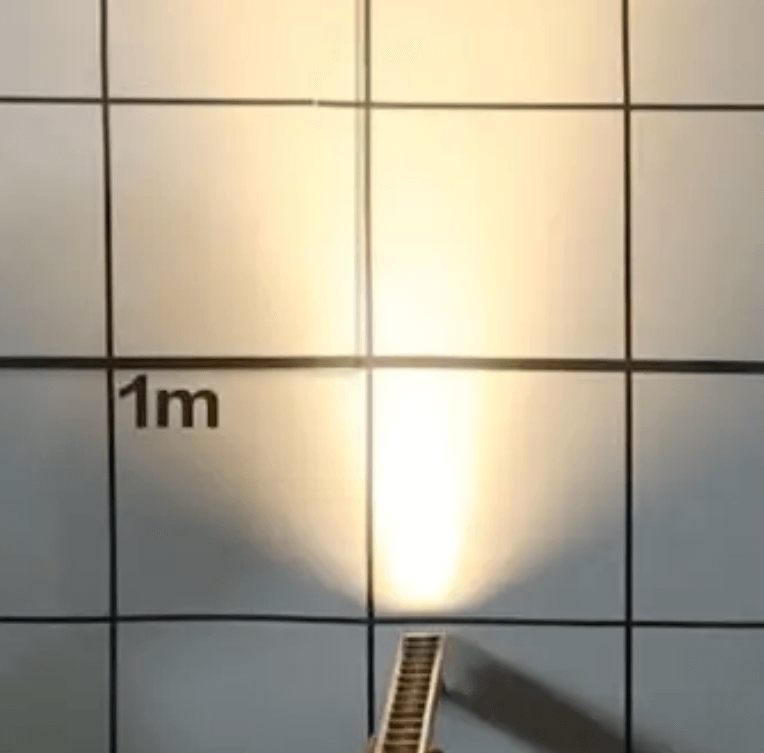

Sometimes, we also add a lens to the light bar, so that the light can produce the effect we want, so the hard light bar is often used for wall-washing, which is why it is called a wall washer.

On each of the lamp beads, a ribbed lens is added for light distribution.

Vertical is a narrow light distribution

Horizontally wide

6 Support

Of course, there are some more complicated ones, basically a complete luminaire, such as the bracket we often say, the appearance is similar to the traditional fluorescent lamp bracket.

It is equipped with a wire head and a connector, which can be stringed together to grow a long line. Of course, the length of the specific string can be consulted. Some products will make the ends of the acrylic transparent, so there is almost no dark area after lighting.

In terms of use, it can be used as an alternative to fluorescent lamp brackets, or can be hung in ceiling for simple lighting, such as garages and warehouses, where lighting is not required.

Finally, a principle is emphasized: the products are selected according to the needs, and the products are selected according to the characteristics of the place. For example, we just said that there will be no dust, no need to have a sheath, not only to see the advantages of the protective cover, its shortcoming is that it may lose a little light. So understand the product, understand the application site, understand the needs, and choose the right product.